This project serves as the foundation for both a future product idea and the development of a Grasshopper plugin. Initially, it started as an exploration of computationally crafted vases, but as my interest in fabricating these vessels grew, I delved into expanding and refining my concept. My ultimate goal is to establish a streamlined process capable of generating a wide range of design solutions in a timely manner. This necessitates a clear vision of the design space I wish to explore and the creation of a reliable workflow for generating fabrication instructions.

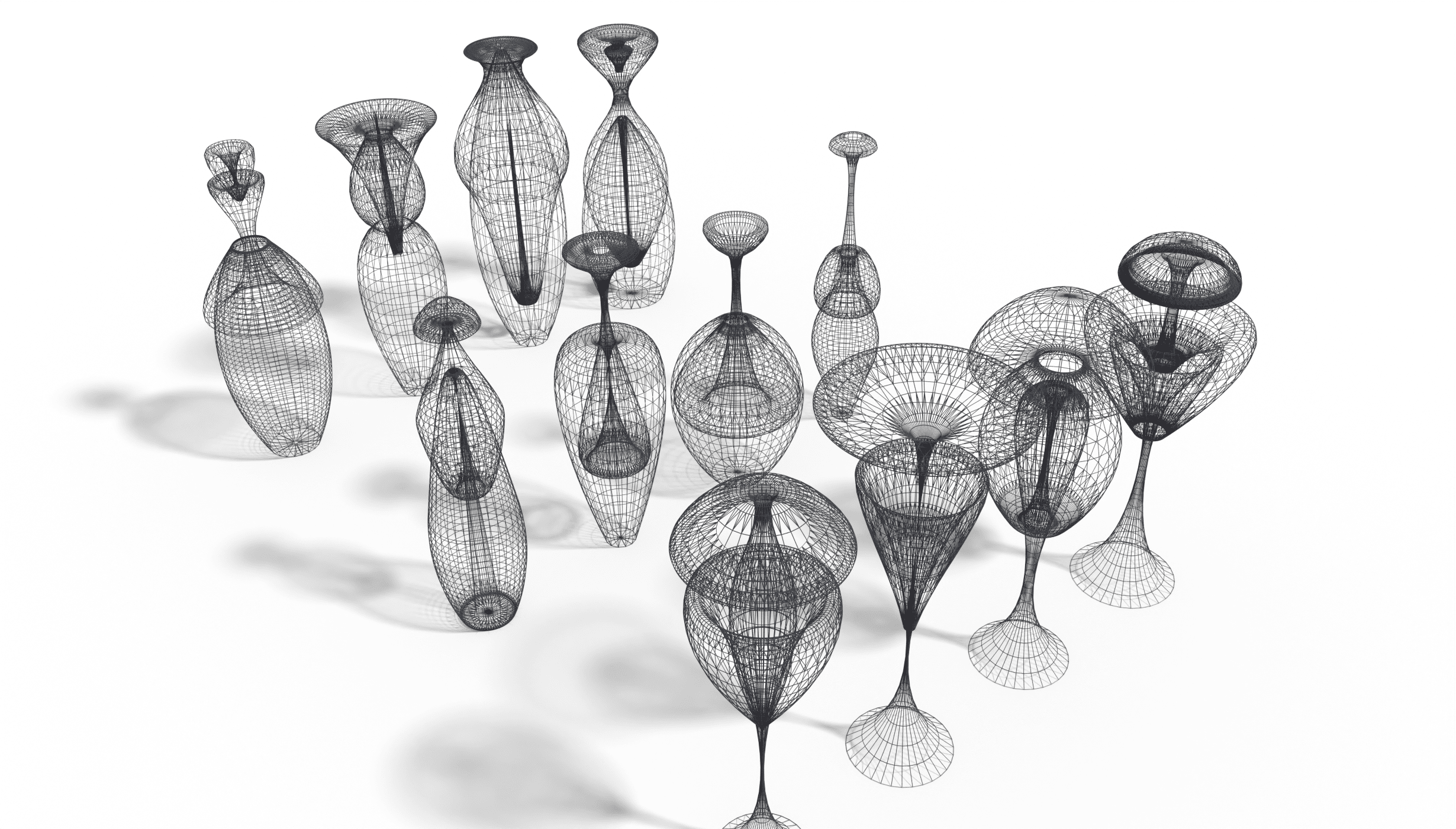

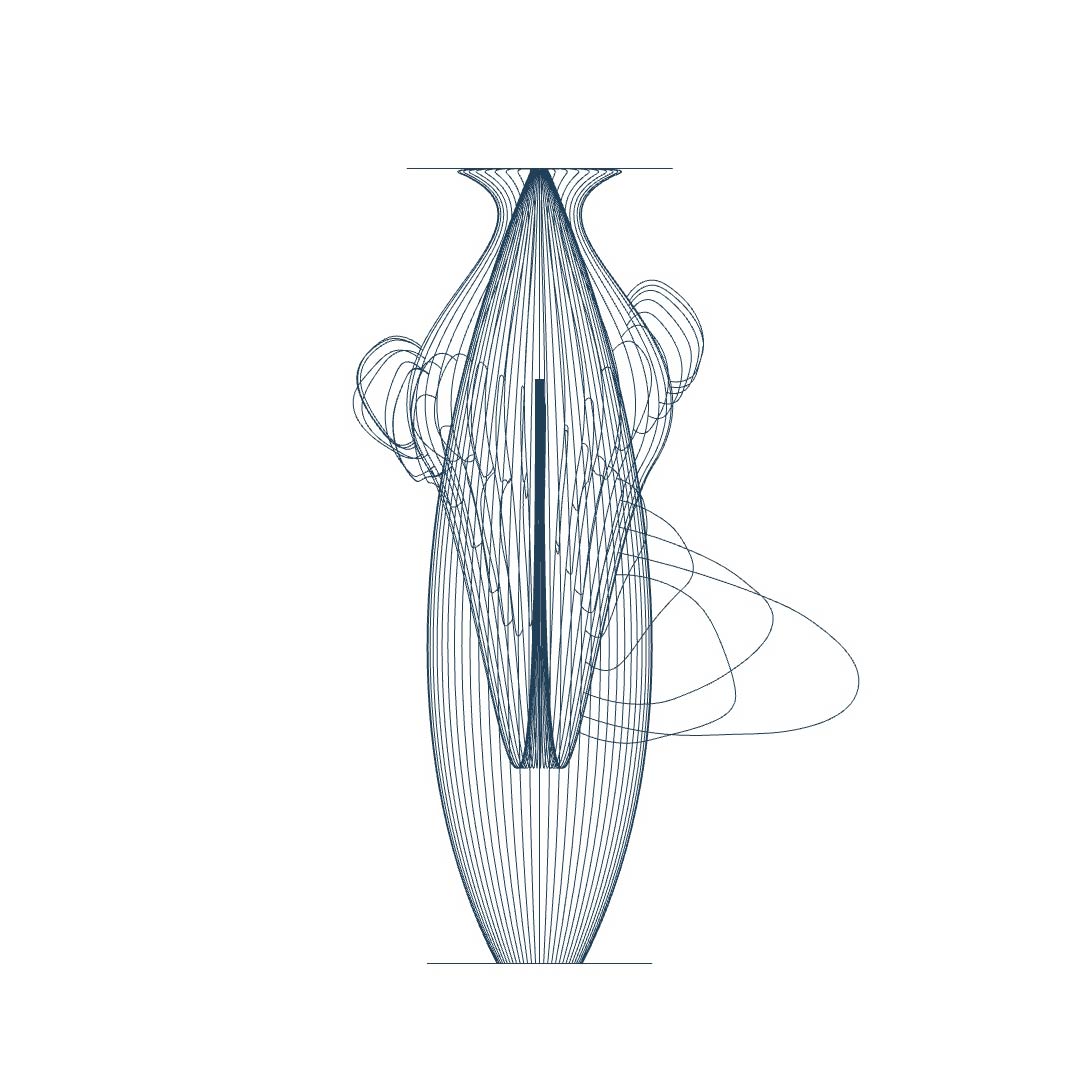

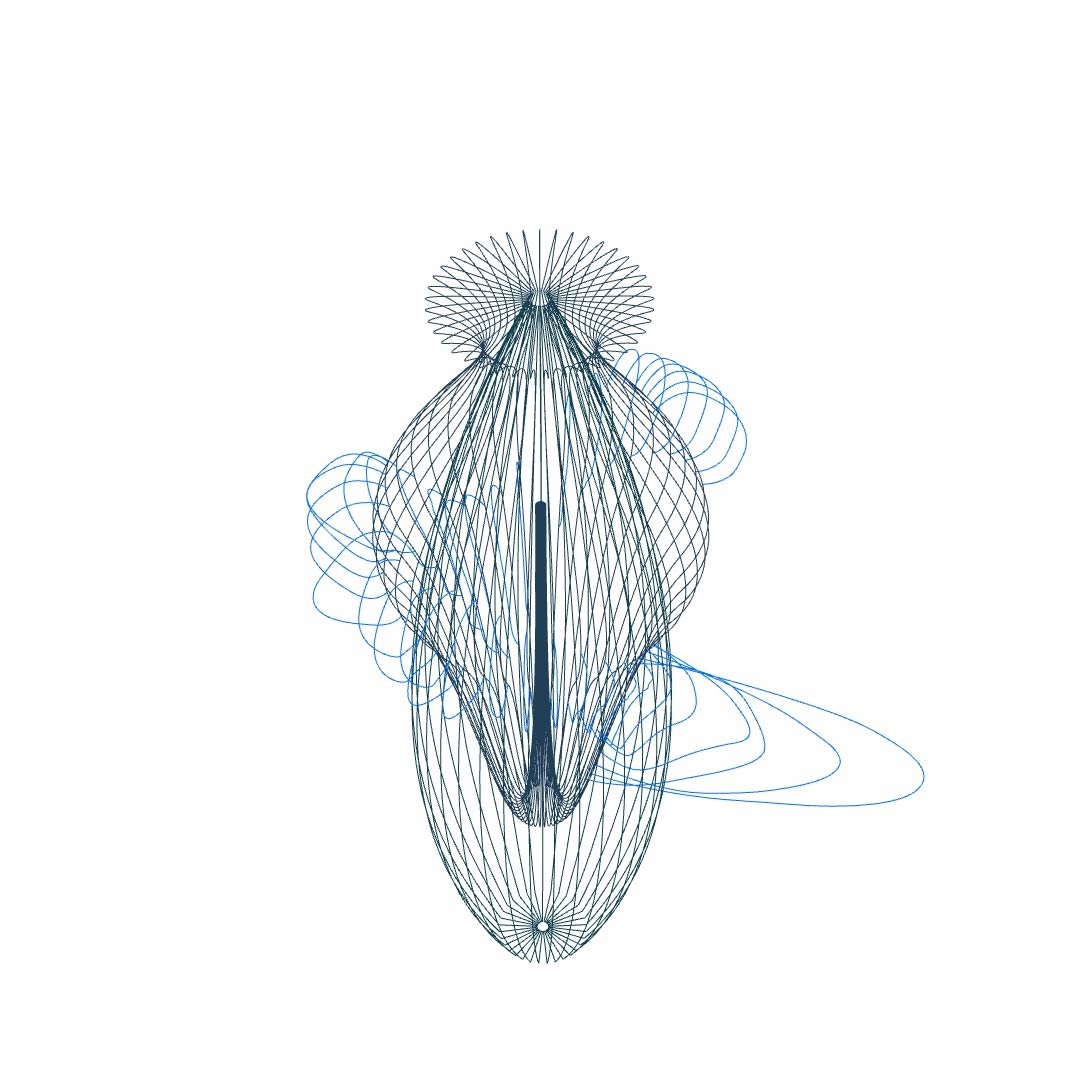

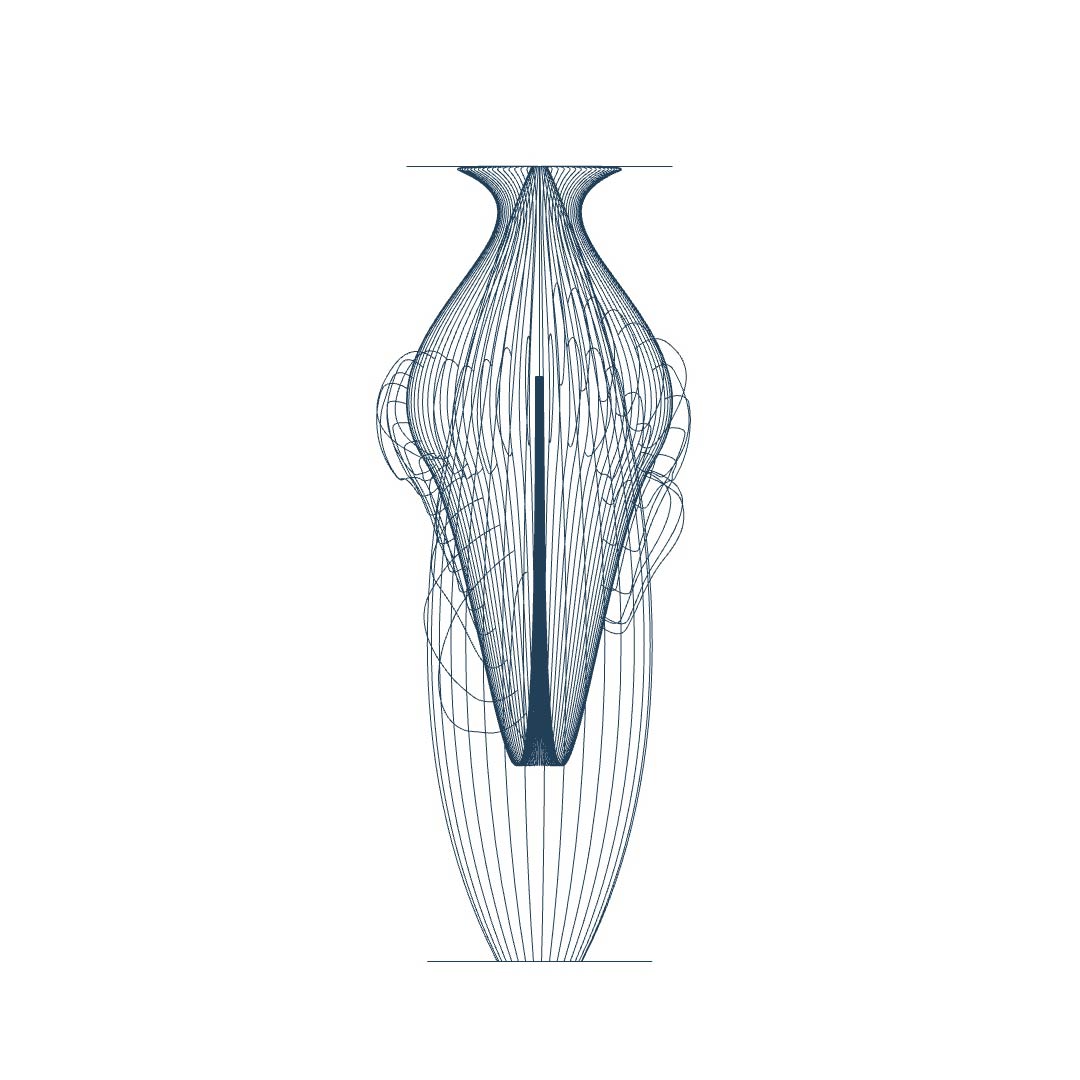

My objective is to produce vessels starting from complex, self-intersecting curves. I aim to physically realize these intersecting geometries using a flat pack method that incorporates vertical louvres, also known as "fins," to give the forms their distinct shape. To kickstart the process, I begin by sketching an arbitrary bezier curve and iteratively refining it until I achieve an intriguing profile curve, which serves as my input.

As part of this project, I have started sketching the essential components of a plugin required to process the input curve through a Grasshopper script. If the curve contains self-intersections, it undergoes strategic splitting at discontinuity points. Each resulting sub-domain of the curve is then revolved and replicated around an axis. To address potential collisions caused by self-intersections, I offset each distinct group of curves along the axis, ensuring they fit into empty spaces without overlapping. Additionally, I have incorporated aesthetic features to introduce variety and break the radial symmetry of each form.

However, there are still crucial steps remaining. I need to create the disk joinery that accommodates the fins, allowing for secure assembly. Furthermore, I must incorporate dimension and depth into the curve geometry to add visual interest and enhance the overall design. Once the design process is complete, I plan to fabricate these vessel forms using either CNC milling or laser cutting techniques. These manufacturing methods will bring the digital designs to life, resulting in tangible and visually captivating objects.

Through this project, I aim to showcase the potential of computational design in generating diverse vessel forms while pushing the boundaries of traditional fabrication techniques. By combining digital geometry, iterative refinement, and precise manufacturing, I strive to produce aesthetically appealing and functional objects that exemplify the fusion of creativity and technology.